Boulter Plywood in Summerville, MA carries ( 1/16 ?) and 1/8 okoume plywood for a fraction of the cost of the on line hobby stores.

They also carry Baltic Birch plywood: 1/16'' and 1/8''

http://www.boulterplywood.com

toll free at 888 - 9 LUMBER. (888) - 958 - 6237

or Email: chris@boulterplywood.com

--

Okoume Plywood Information:

1.Face / back: okoume Core: poplar, hardwood, pine ,

2.Size: 1,220 x 2,440mm, 1,250mm x 2,500mm, 915 x 1,830mm or as requested

3.Thickness: 3.5mm-30mm

4.Glue: WBP, MR, E1, E2

--

Wood Properties of Okoume from

http://www.connectedlines.com/wood/wood47.htm

Okoume Alternative Name 1

Gaboon

Okoume Available as Veneer

Yes

Okoume Bending Strength

Moderate

Okoume Blunting of Tool Blades

Moderate to Severe

Okoume Botanical Name

Aucoumea klaineana

Okoume Carving

Average to somewhat difficult to carve

Okoume Clear Finish or Varnish

Fair

Okoume Color of Wood

Pink Brown

Okoume Density

Low

Okoume Drilling

Fair or Satisfactory

Okoume Gluing

Good

Okoume Grain

Mostly Straight

Okoume Hand Tooling

Average

Okoume Hardness

Soft, easy to dent

Okoume Hardwood or Softwood

Hardwood

Okoume Harmful Properties

Non Toxic

Okoume Mortising

Fair or satisfactory

Okoume Nail Holding

Good- Nails are fairly difficult to pull out

Okoume Nailing

Fair - may require pre-drilled pilot hole especially near ends

Okoume Natural Durability

Non-durable

Okoume Polishing

Good

Okoume Sanding

Fair or satisfactory

Okoume Sawing

Moderate cutting resistance

Okoume Screw Holding

Good - Fairly difficult to remove screws

Okoume Screwing

Fair - May require pre-drilled pilot holes especially near ends

Okoume Size of Pores

Insufficient Data Available

Okoume Staining

Fair - May stain unevenly or change colors

Okoume Steam Bending

Poor

Okoume Stiffness

Low

Okoume Surface Preparation for Finishing

No

Okoume Texture of the Wood

Intermediate

Okoume Weight

Light

Okoume Wood Defects

Check (or split,) warp

Model Boats and wooden boats

Videos and more

mainwaring @ rcn.com

A member of Dave Mainwaring's Knowledge-Network

Thursday, November 06, 2008

Saturday, November 01, 2008

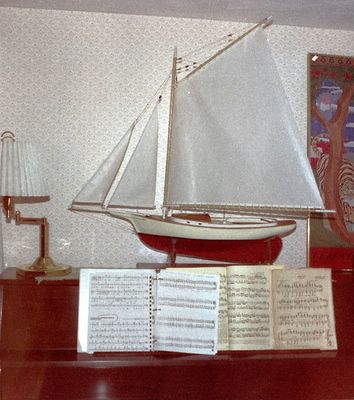

R/C model Friendship Sloop

Pemiquid style Friendship Sloop R/C ,model

Friendship Sloop - Pemiquid

Jonesport model under construction, , 42 inch glass hull

42in_lb_model_10.jpg

Posted by target='ext'>Hello

42in_lb_model_03.jpg

Posted by Hello

Dave Mainwaring, 42 inch model under construction

Fibre Glast Developments _ Estimating Materials

The Fundamentals of Fiberglass - Fibre Glast Developments: "Worksheet For Estimating Materials

1) Begin by calculating the surface area of the project. Estimate irregular shapes by measuring the approximate sized rectangles necessary to contain the tapered areas. Multiply the length times the width for each rectangle, and then add all of individual rectangles together to get the total surface area of the part. If the calculation is in square feet, divide by 9 to get square yards.

2) Make a list of each type of reinforcement being considered for the lamination. Multiply the square yards calculated above times the ounce weight of the fabric. This is the total weight of one layer of that material. It is also the amount of resin required to saturate it. When this is known for two or three different types of materials, it is possible to calculate the weight and cost of a laminate constructed from any combination of these fabrics. To convert the ounce weight to pounds, divide by 16. Those inexperienced in saturating fiberglass tend to use far too much resin. A well saturated laminate is uniformly translucent, without milky appearing dry spots, but for the sake of weight and cost, has little excess resin in it."

1) Begin by calculating the surface area of the project. Estimate irregular shapes by measuring the approximate sized rectangles necessary to contain the tapered areas. Multiply the length times the width for each rectangle, and then add all of individual rectangles together to get the total surface area of the part. If the calculation is in square feet, divide by 9 to get square yards.

2) Make a list of each type of reinforcement being considered for the lamination. Multiply the square yards calculated above times the ounce weight of the fabric. This is the total weight of one layer of that material. It is also the amount of resin required to saturate it. When this is known for two or three different types of materials, it is possible to calculate the weight and cost of a laminate constructed from any combination of these fabrics. To convert the ounce weight to pounds, divide by 16. Those inexperienced in saturating fiberglass tend to use far too much resin. A well saturated laminate is uniformly translucent, without milky appearing dry spots, but for the sake of weight and cost, has little excess resin in it."

The Fundamentals of Fiberglass - Fibre Glass Developments

The Fundamentals of Fiberglass - Fibre Glass Developments: "Estimating Material Weights And Cost

Accurate material estimates are necessary for two reasons.First, they obviously are needed for proper ordering, material stocking, and bidding of projects. More importantly though, estimates offer the opportunity to calculate the weight or cost of the part using a variety of laminating schedules before beginning to build.

Unlike estimating coverage when painting, resin usage will vary depending on the type of reinforcement being used. The heavier the fabric, the more resin it will take to wet it out. A good hand laminate consists of about 50% fabric and 50% resin by weight. For example, if an application requires 3 sq yds of a 4 oz/sq yd fabric (total fabric weight = 12 ounces), 12 oz of resin will also be needed. However, if 3 yards of 10 oz/sq yd fabric is chosen (total fabric weight = 30 ounces), 30 oz. of resin will be needed.

Glass mat requires a minimum of 2 ounces of resin for each ounce of mat. Therefore, it the application calls for 20 sq feet of 1-1/2 oz/sq ft mat, it will require a minimum of 60 ounces of resin. Remember that mat is specified in ounces per square foot, where fabrics are specified in ounces per square yard. 1-1/2 oz/ sq ft chopped mat actually weighs 13.5 oz/ sq yd!

Since there are so many possible combinations of materials, one should calculate the weight and cost of a single layer using a variety of reinforcements. These can then be added or subtracted form the theoretical laminate until the design properties are achieved."

Accurate material estimates are necessary for two reasons.First, they obviously are needed for proper ordering, material stocking, and bidding of projects. More importantly though, estimates offer the opportunity to calculate the weight or cost of the part using a variety of laminating schedules before beginning to build.

Unlike estimating coverage when painting, resin usage will vary depending on the type of reinforcement being used. The heavier the fabric, the more resin it will take to wet it out. A good hand laminate consists of about 50% fabric and 50% resin by weight. For example, if an application requires 3 sq yds of a 4 oz/sq yd fabric (total fabric weight = 12 ounces), 12 oz of resin will also be needed. However, if 3 yards of 10 oz/sq yd fabric is chosen (total fabric weight = 30 ounces), 30 oz. of resin will be needed.

Glass mat requires a minimum of 2 ounces of resin for each ounce of mat. Therefore, it the application calls for 20 sq feet of 1-1/2 oz/sq ft mat, it will require a minimum of 60 ounces of resin. Remember that mat is specified in ounces per square foot, where fabrics are specified in ounces per square yard. 1-1/2 oz/ sq ft chopped mat actually weighs 13.5 oz/ sq yd!

Since there are so many possible combinations of materials, one should calculate the weight and cost of a single layer using a variety of reinforcements. These can then be added or subtracted form the theoretical laminate until the design properties are achieved."

Subscribe to:

Comments (Atom)